The Mountain Villager

Volume V, Number 16, April 17, 1997

By Stephanie M. Urie

Mountain Villager Correspondent Waterville – The quantity, quality and caliber of maple syrup flowing out of the operation at five-year-old Green Mountain maple Sugar Refining Co. here is garnering widespread recognition and respect.

Waterville – The quantity, quality and caliber of maple syrup flowing out of the operation at five-year-old Green Mountain maple Sugar Refining Co. here is garnering widespread recognition and respect.

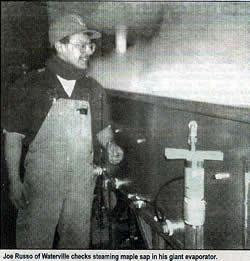

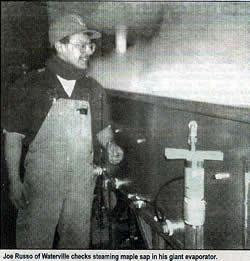

Not just another sugar maker, owner Joe Russo designed state-of-the-art equipment to process the sap from his 25,000 hillside taps. A custom-engineered steam pan evaporates the clear sap into mostly fancy and medium syrup the he sells.

One day this season found Russo tending the syrup while exuberantly narrating an educational documentary for a film crew, posing for photographs for national gourmet magazine and talking with two journalists.

Such acclaim is due to the care Russo has invested in his crop. George Cook University of Vermont Extension Service maple specialist, said, “This is probably the most modern and up-to-date sugaring operation in the area. The technology and safety features are seven steps ahead of the rest of us.”

“To make quality of a large quantity is difficult,” Russo said. “But, I’ve been able to supersede my expectations because of the speed with which the sap goes through [the process].”

Russo engineered a custom evaporator that measures 10-feet by 8-feet by 2-feet. David Albright, of Jeffersonville constructed the innards of the behemoth. The steam pan has no arch and, hence, is without a direct fire underneath. Instead, the pan is fired by a colossal oil burner that creates steam that threads its way through hundreds of feet of copper tubing – while ingesting 75 gallons of fuel an hour. “Just think, a gourmet food product from the forest without harvesting timber,” said Russo. The sap flows in plastic tubing from the trees downhill into a holding tank, then runs by 16 ultraviolet light bulbs which purify it, killing bacteria. This contributes the quality and grade of his syrup. A reverse-osmosis machine draws water away from the sap and the resulting sugar water is pre-warmed to 140 degrees.

Continue reading →

What do you think of when you think of sugaring—buckets and gathering tubs, or tubing and vacuum? It is interesting that most photographs of sugaring feature the old style. If you go to Google Images and search for “maple sugaring,” you will find many pictures of buckets but not many pictures of tubing. We are nostalgic about our past. Even at Yankee Farm Credit: the back cover of our 2008 annual report features a sugaring photo that is more old than new.

What do you think of when you think of sugaring—buckets and gathering tubs, or tubing and vacuum? It is interesting that most photographs of sugaring feature the old style. If you go to Google Images and search for “maple sugaring,” you will find many pictures of buckets but not many pictures of tubing. We are nostalgic about our past. Even at Yankee Farm Credit: the back cover of our 2008 annual report features a sugaring photo that is more old than new.